Note: When threading the machine, first fill the bobbin before threading the top thread.

Video Tutorials

Winding the Bobbin

1

Place a spool of thread on the spool pin, and secure it with the spool pin cap. Pull the thread out from the spool and place it through thread guides as shown in the illustration.

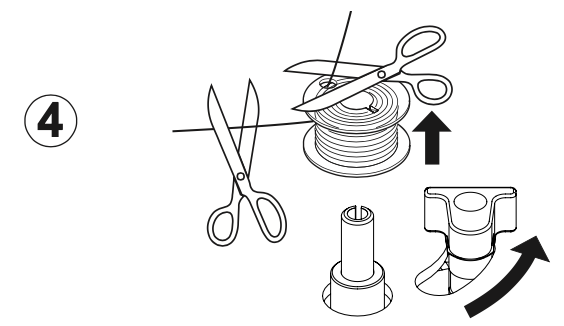

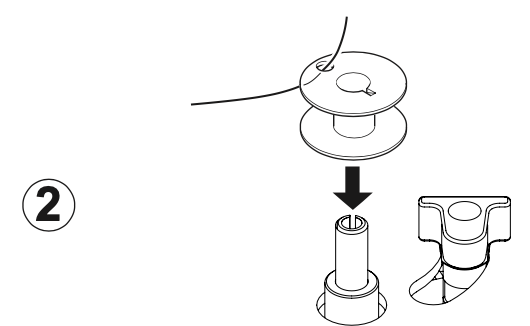

2

Put the end of the thread through the hole in the bobbin as shown. Place the bobbin onto the bobbin winder spindle as far as it can go.

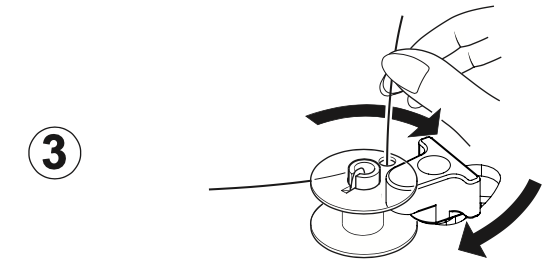

3

Holding onto the end of the thread, push the bobbin winder latch against the bobbin until it clicks and the bobbin starts to rotate.

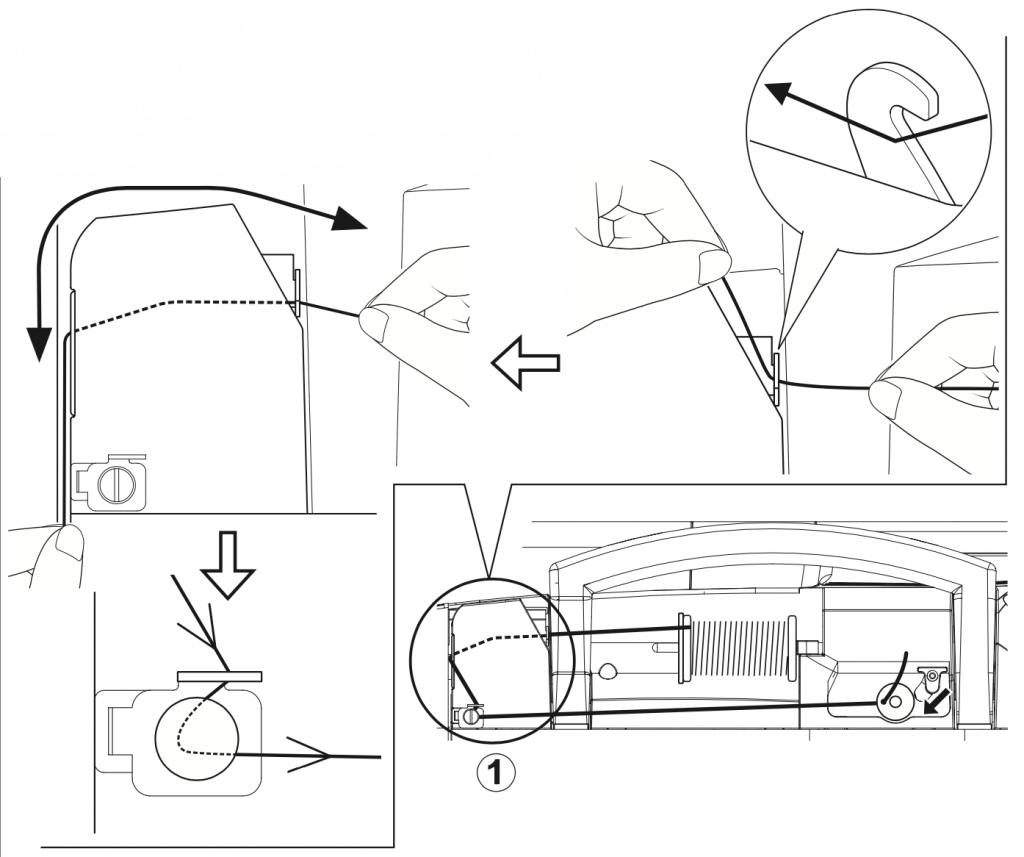

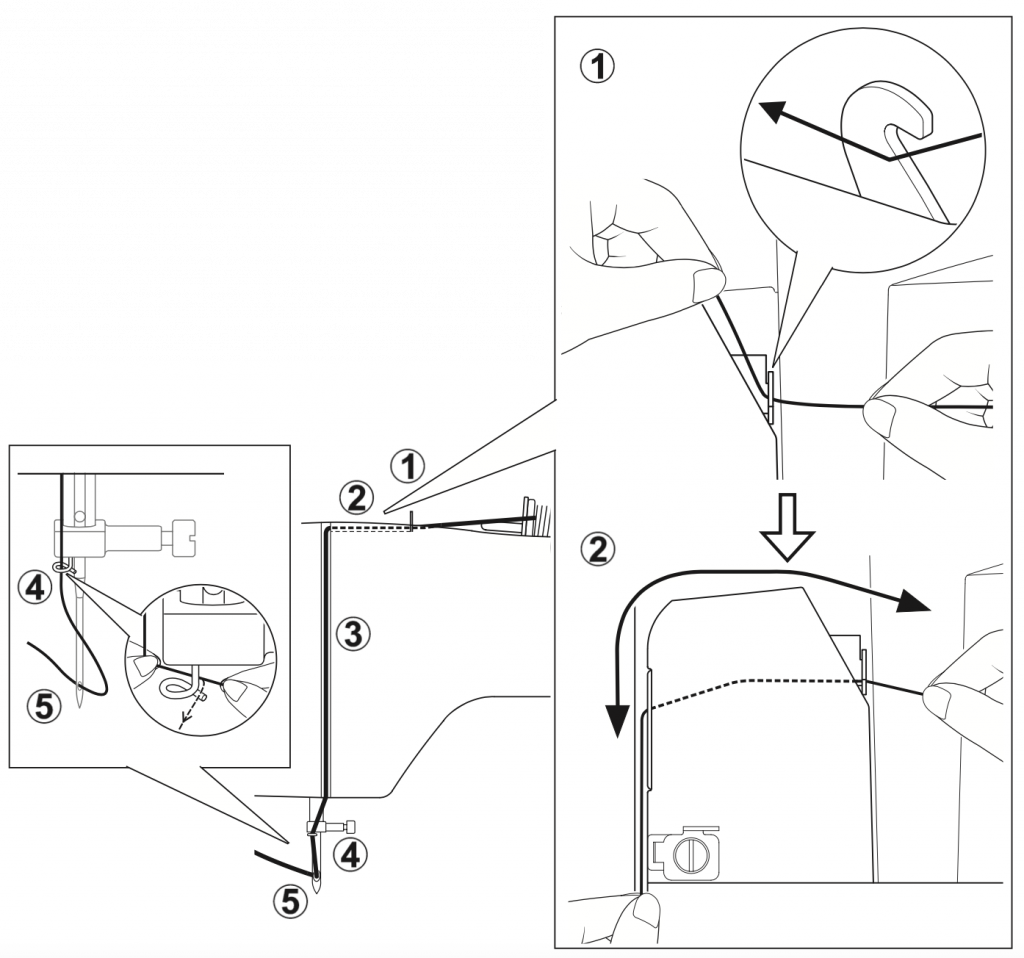

Threading the Bobbin Thread

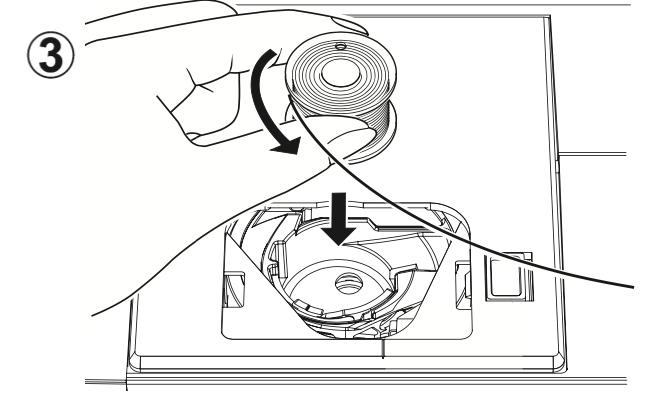

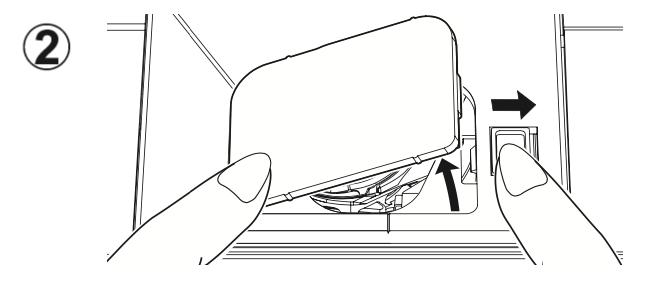

2

Remove the bobbin cover plate by pushing the release button to the right. Bobbin cover will pop up sufficiently to allow you to remove the cover.

Note: This is a very important step. The bobbin must rotate counterclockwise when the thread is pulled.

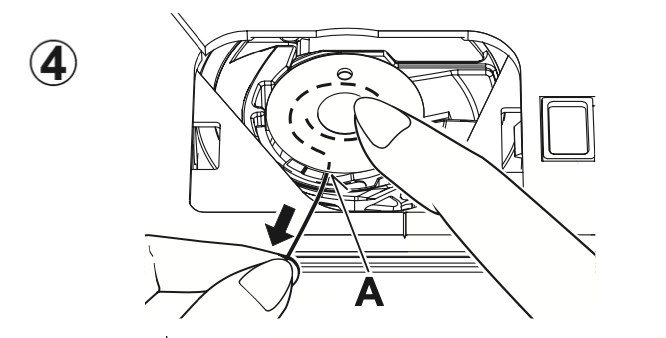

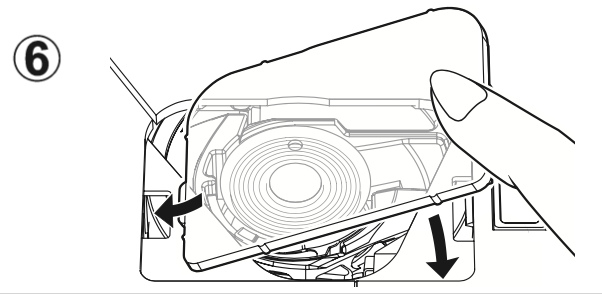

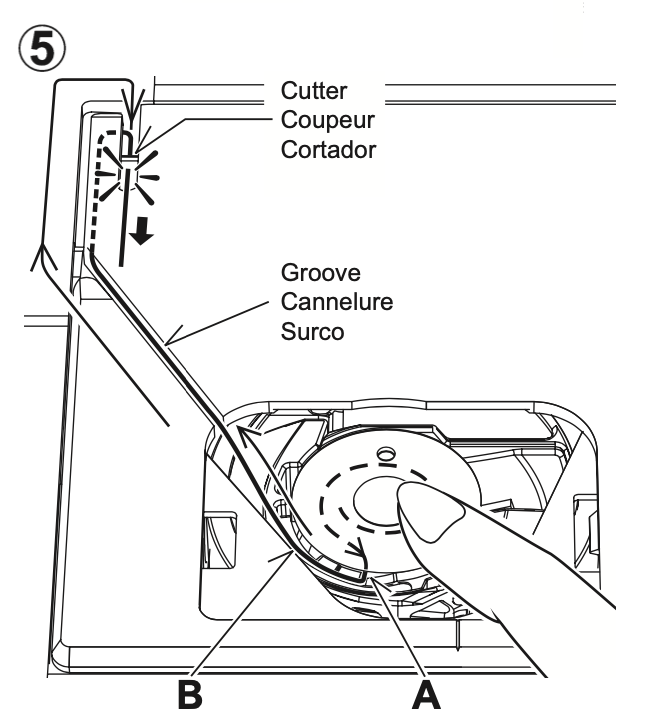

5

With a finger held gently on top of the bobbin, pull the thread until it stops in the slot (B). Then pull the thread along the groove on the needle plate until it is snipped with cutter on the top left.

Note: Sewing can be started without having to pull up the bobbin thread.

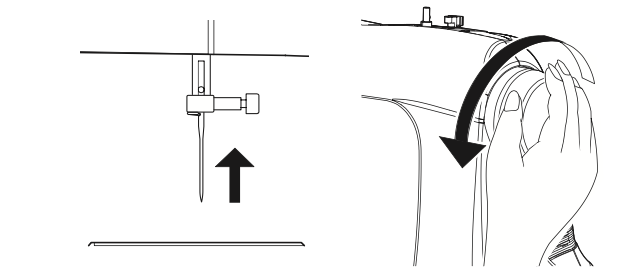

Threading the Top Thread

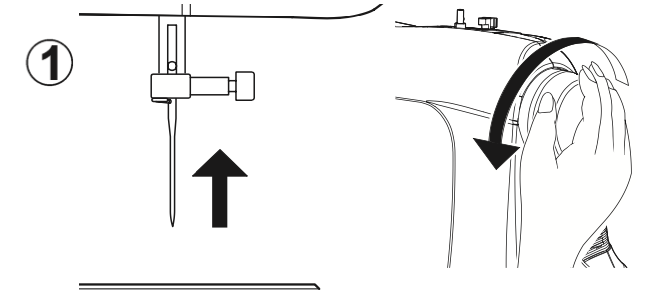

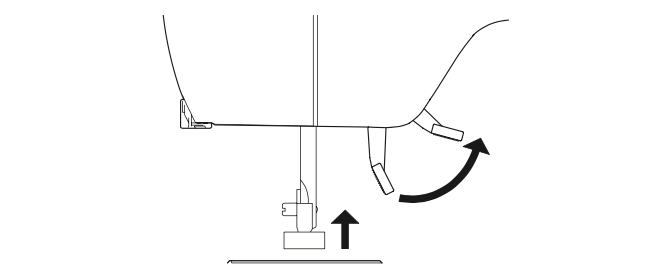

1

Raise the presser foot lifter. Always be sure to raise the presser foot lifter before threading the top thread. (If the presser foot lifter is not raised, correct thread tension cannot be obtained.)

3

Thread the machine with your left hand while firmly gripping the thread with your right hand in the following order as illustrated.

- Guide the thread through thread guides (1 & 2), and then pull it down along the groove (3).

- Guide the thread into the thread guide (4).

- Pass the thread through the eye of the needle (5) from front to back.

Important

To verify that the machine is threaded properly in the tension discs, do this simple check:

- With the presser foot raised, pull the thread towards the back of the machine. You should detect only slight resistance and little or no deflection of the needle.

- Now lower the presser foot and again pull the thread towards the back of the machine. This time you should detect a considerable amount of resistance and much more deflection of the needle. If you do not detect the resistance you have miss-threaded the machine and need to re-thread it.